Everything you need to know before buying — types, prices, suppliers & pro tips

Why Guwahati’s Construction Boom Is Driving Brick Machine Demand

Guwahati is growing fast. New residential colonies, commercial complexes, and government infrastructure projects are reshaping the city’s skyline every year. At the heart of every one of these projects is a single, humble material: the brick. And powering brick production across Assam’s largest city is an increasingly popular piece of equipment — the manual brick making machine.

Whether you’re a small-scale contractor, an entrepreneur starting a brick manufacturing business, or a construction professional looking to cut costs, a manual brick making machine in Guwahati can give you a significant competitive advantage. It lets you produce durable, consistent bricks on-site without dependence on unreliable supply chains.

In this guide, we cover everything: what a manual brick machine is, the types available, how much it costs, where to buy in Guwahati, and what to look for before making your investment.

What Is a Manual Brick Making Machine?

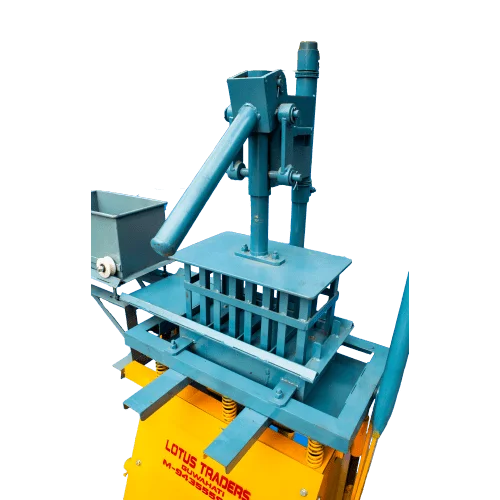

A manual brick making machine is a device operated by human labor — not electricity or automated systems — to compress raw materials like cement, fly ash, clay, sand, and water into standardized brick shapes. Unlike semi-automatic or fully automatic machines, manual machines have no electronic components, making them simpler to operate, easier to maintain, and far more affordable.

According to Lotus Traders Guwahati, manual brick machines are ideal for small and medium-scale operations where flexibility, low capital investment, and ease of use are top priorities. The operator controls the compression lever or handle, and bricks are ejected from interchangeable molds that determine the size and shape of the output.

These machines are especially popular in Northeast India, where power supply can be intermittent and where many construction projects happen in areas far from established factories.

Types of Manual Brick Making Machines Available in Guwahati

Not all manual brick machines are built the same. Here’s a breakdown of the main types you’ll find from suppliers in and around Guwahati:

1. Single Cavity Manual Brick Machine

The most basic type, producing one brick per cycle. Best for very small-scale operations or individual builders. Low cost, very portable, and easy to learn. Typically produces standard 9″ x 4.5″ x 3″ bricks.

2. 4-Cavity Manual Brick Machine

One of the most popular options in Guwahati. The 4-cavity machine produces four bricks per press cycle, dramatically increasing output. Guwahati suppliers lists this type starting at approximately ₹58,000 to ₹70,000 per unit — making it a practical first investment for entrepreneurs.

3. Interlocking Manual Brick Machine

Produces interlocking bricks that lock together without mortar. This is gaining popularity in Guwahati for low-cost housing and rural infrastructure projects, as it reduces both materials cost and construction time significantly.

4. Fly Ash Manual Brick Machine

Uses fly ash — a byproduct from coal thermal plants — as the primary raw material. These bricks are lighter, stronger, and more eco-friendly than clay bricks. As noted in a guide by Columbia Machine India, fly ash bricks are resistant to water, termites, and fire, making them highly reliable for long-term use.

5. Hydraulic-Lever Manual Brick Machine

This type uses a hydraulic lever mechanism to apply high pressure during compression. It requires more effort per cycle but produces denser, higher-strength bricks. Available from Guwahati-based manufacturers like M/s Jyoti Construction Materials, with production capacities of up to 3,000 blocks per shift at 1 HP power consumption.

Manual Brick Making Machine Price in Guwahati: What to Expect

One of the most common questions from buyers is: how much does a manual brick making machine cost in Guwahati? The answer depends on the type, capacity, and supplier. Here’s a general price overview:

- Basic single-cavity manual machine: ₹25,000 – ₹45,000

- 4-cavity manual cement brick machine: ₹58,000 – ₹77,000

- Hydraulic lever manual machine: ₹1,20,000 – ₹1,60,000

- Fly ash manual brick machine: ₹45,000 – ₹1,00,000

- Interlocking brick manual machine: ₹80,000 – ₹1,50,000

These prices reflect ex-factory rates. You may need to budget additional amounts for transportation to your site, GST (18%), installation, and initial raw materials. For a detailed price comparison from verified Guwahati suppliers, visit IndiaMART Guwahati or TradeIndia to request live quotes.

Key Benefits of Using a Manual Brick Making Machine

Why are so many small contractors and entrepreneurs in Guwahati choosing manual machines over automatic ones? Here are the top reasons:

1. Low Initial Investment

Manual machines cost a fraction of semi-automatic or fully automatic alternatives. This makes them perfect for startups and small businesses entering the brick manufacturing space without a large capital base.

2. No Electricity Required

In areas of Guwahati and surrounding Assam districts where power cuts are common, manual machines offer uninterrupted production. There’s no dependence on the grid, diesel generators, or electrical components.

3. Easy to Operate and Train Staff

As Lotus Traders notes, manual brick machines have a simple design that workers can learn quickly. This means lower training costs and faster deployment on construction sites.

4. Versatile Brick Output

By simply swapping the mold, operators can produce different brick sizes, shapes, and types — from standard solid bricks to hollow blocks and paver tiles. This flexibility makes one machine serve multiple construction needs.

5. Low Maintenance Costs

With fewer mechanical parts and no electronic components, manual machines rarely break down. When maintenance is required, spare parts are readily available locally in Guwahati and are inexpensive.

6. Portable and Site-Friendly

Manual machines are compact and can be transported to remote construction sites across Assam with ease — something that large automatic machines simply cannot match.

How to Choose the Right Manual Brick Making Machine in Guwahati

With so many options available, selecting the right machine requires careful thought. Here are the five key factors to evaluate:

- Daily Production Target: Estimate how many bricks you need per day. A 4-cavity machine can typically produce 2,000–3,000 bricks per shift with a standard crew of 4–6 workers.

- Brick Type: Decide whether you need solid bricks, hollow blocks, fly ash bricks, or interlocking bricks — then choose a machine with compatible molds.

- Raw Materials Available: Guwahati and surrounding areas have good availability of clay, sand, and cement. If you’re near a thermal power plant, fly ash is also accessible and cost-effective.

- Build Quality: Look for heavy-gauge MS (mild steel) frame construction, robust mold cavities, and smooth compression mechanisms. Inspect samples from the manufacturer before ordering.

- After-Sales Support: Prioritize suppliers who offer warranty, spare parts availability, and local service in Guwahati or Assam.

Where to Buy a Manual Brick Making Machine in Guwahati

Guwahati has a growing ecosystem of brick machine suppliers. Here are some reliable options to explore:

- M/s Jyoti Construction Materials – Hangrabari, Goneshguri, Guwahati. A local manufacturer with machines starting at ₹45,000 and production capacity of 2,000 bricks per shift.

- Guwahati Machinery – Offers a full range from manual to automatic machines, with strong customer reviews and transparent pricing.

- Lotus Traders Guwahati – Specializes in 4-cavity manual machines and concrete brick making equipment.

- IndiaMART & TradeIndia – Online platforms to compare multiple Guwahati and Assam-based verified suppliers side by side.

- Justdial Guwahati – Useful for finding nearby dealers with customer ratings and contact details.

Before finalizing any purchase, always request a live demonstration, verify the machine’s GST registration, and ask for customer references in your region.

Pro Tips to Maximize Your Brick Machine ROI

Getting the machine is just the start. Here’s how experienced operators in Guwahati maximize returns:

- Mix proportions matter: Maintaining the right cement-to-sand or fly ash ratio directly affects brick strength. Test batches before scaling up production.

- Curing is critical: Manually made bricks need proper curing — keep them moist for at least 7 days to develop full compressive strength.

- Schedule maintenance: Even simple machines need lubrication of moving parts, mold cleaning, and frame inspection every 2–4 weeks.

- Track production per shift: Know your output per worker per shift to identify inefficiencies and manage labor costs effectively.

- Explore government schemes: Assam state government and MSME schemes may provide subsidies or low-interest loans for brick manufacturing units — check with your local District Industries Centre (DIC).

The Bigger Picture: Brick Manufacturing in Northeast India

India is the world’s second-largest brick producer, with annual output exceeding 250 billion bricks and the sector growing at a CAGR of approximately 8%, according to data cited by HYPKO. Northeast India — and Guwahati in particular — is a significant growth market, driven by the government’s Smart Cities Mission, PM Awas Yojana (PMAY), and major road and bridge infrastructure projects across Assam.

For entrepreneurs in Guwahati, the timing could not be better. A manual brick making machine offers a low-risk entry point into a market with sustained, long-term demand. With the right machine, the right location, and access to affordable raw materials, a small brick making operation can achieve a return on investment within 6 to 12 months.

Conclusion: Ready to Build Smarter in Guwahati?

A manual brick making machine in Guwahati is more than a piece of equipment — it’s a business opportunity and a construction solution rolled into one. Whether you’re a contractor looking to produce bricks on-site, or an entrepreneur launching a brick manufacturing unit, the right manual machine can reduce your costs, improve your material quality, and strengthen your competitive edge.

Start by identifying your daily output target, evaluating the types of bricks your projects require, and comparing verified local suppliers. Request demonstrations before buying, and don’t overlook government support schemes available to manufacturing SMEs in Assam.

Your next construction project doesn’t have to rely on third-party brick suppliers with unpredictable prices and delivery delays. With a manual brick machine, you’re in control — from raw material to finished brick, all on your own terms.